Usual Difficulties in Welding Inspection Madison and How to Overcome Them

Usual Difficulties in Welding Inspection Madison and How to Overcome Them

Blog Article

Exactly How Efficient Welding Examination Boosts Architectural Integrity and Durability

In the world of building and design, the relevance of welding examination can not be overstated, as it plays a crucial function in making certain architectural integrity and prolonging the lifespan of jobs. Join the exploration of exactly how effective welding assessments can change possible vulnerabilities right into staminas, contributing to the enduring success of buildings.

Importance of Welding Assessment

Ensuring the architectural honesty and security of bonded constructions mandates extensive welding examination processes. Welding inspection offers as a critical secure in the construction and production sectors, where the toughness and sturdiness of joints substantially impact the overall efficiency of frameworks.

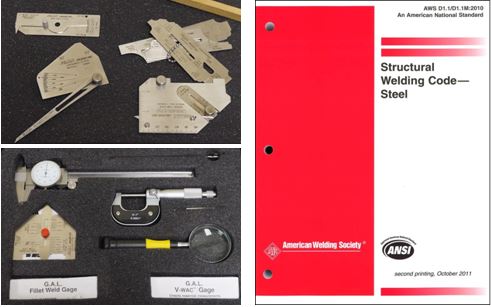

Along with security, welding assessment plays a crucial function in quality control. By sticking to established criteria, inspections ascertain the uniformity of welds, making sure that each satisfies the desired stamina and aesthetic needs. This consistency is necessary not only for safety yet additionally for keeping the track record and reliability of erectors and suppliers. Governing compliance is a significant vehicle driver of welding evaluation techniques. Industry criteria and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), necessitate adherence to rigorous guidelines, emphasizing the significance of examinations in fulfilling these lawful and professional responsibilities.

Secret Examination Methods

Ultrasonic Examining (UT) utilizes high-frequency acoustic waves to detect subsurface flaws, supplying specific details concerning weld integrity without creating any type of damage. Radiographic Testing (RT), entailing X-rays or gamma rays, provides an in-depth picture of the weld's internal framework, revealing concealed imperfections. Magnetic Fragment Checking (MPT) is an additional non-destructive method, specifically efficient for detecting surface and near-surface suspensions in ferromagnetic materials.

Penetrant Screening (PT) involves the application of a liquid dye to disclose surface-breaking problems, using a economical and simple option for non-porous materials. Each strategy has its specific applications, toughness, and constraints, and usually a mix of techniques is employed to attain extensive assessment results. Proficiency of these strategies improves the integrity and toughness of welded structures, straightening with safety and performance expectations.

Identifying Common Flaws

Porosity, identified by gas pockets within the weld, reduces the weld's stamina and sturdiness. It usually results from contaminants or inappropriate protecting gas. Fractures, which can occur during or after welding, posture considerable dangers due to their potential to propagate under anxiety. They frequently develop from excessive anxiety, rapid air conditioning, or inappropriate weld design.

Incomplete combination, where the weld metal fails to bond completely with the base product, undermines the architectural stability, leading to weak joints. Slag incorporations occur when non-metallic products are trapped in the weld, endangering its stamina and quality.

Identifying these flaws via precise evaluation approaches, such as aesthetic evaluation, ultrasonic testing, or radiography, is important. Resolving these issues guarantees weld high check here quality, ultimately supporting Get More Info the structural honesty and safety and security of the developed environment.

Enhancing Architectural Efficiency

Understanding the significance of recognizing typical weld issues naturally leads to discovering techniques for improving structural performance. The fundamental technique for enhancing efficiency entails employing sophisticated welding strategies and materials that minimize issue incident. Making use of premium filler products and making sure proper warm control can considerably lower issues such as porosity and cracking, consequently boosting the weld's stability.

Incorporating cutting edge welding innovations, such as laser welding and rubbing stir welding, additional enhances architectural resilience. These methods provide superior precision and reduced thermal distortion, straight affecting the longevity and stamina of the welded frameworks. Embracing automated welding systems can make certain repeatable and constant weld top quality, minimizing human mistake.

In addition, carrying out rigorous pre-weld and post-weld procedures is critical. Correct joint layout, surface prep work, and stress-relieving procedures contribute to ideal weld performance. Conducting detailed pre-weld inspections permits early detection of prospective issues, assisting in prompt modifications prior to they endanger the structure.

Long-term Advantages of Inspection

With watchful inspection techniques, the long-term advantages to architectural honesty become significantly obvious. Extensive and regular welding assessments play a critical function in stopping structural failures by identifying disparities and issues early in the building and construction procedure. This positive strategy makes certain that prospective concerns are attended to prior to they can endanger the safety and security and sturdiness of structures. By capturing defects early, pricey fixings and downtime are lessened, inevitably extending the lifespan of the framework.

Moreover, normal inspections add to keeping compliance with market requirements and regulations, thus staying clear of financial and lawful repercussions. This adherence to quality control not just improves the integrity of the structure but likewise cultivates trust fund amongst stakeholders, consisting of clients, designers, and regulatory bodies. The extensive documents of inspection outcomes functions as a useful resource for future repair and maintenance efforts, helping with Bonuses informed decision-making.

On top of that, reliable inspection practices sustain development by including sophisticated technologies such as non-destructive testing and digital imaging, which can improve precision and efficiency. This technical combination better underscores the dedication to quality in architectural honesty. Ultimately, investing in meticulous welding inspections is a sensible method that yields substantial long-term benefits, securing both the physical and monetary investment in facilities tasks.

Conclusion

Effective welding assessment plays an essential function in boosting structural honesty and durability by identifying defects early in the building process. Making use of techniques such as aesthetic assessment, ultrasonic testing, and radiographic screening makes sure the detection of problems like fractures and porosity that compromise weld stamina. Strenuous inspections guarantee compliance with sector standards, thereby lengthening the lifespan of frameworks, decreasing expensive repair work, and promoting stakeholder count on the reliability and security of welded building and constructions.

In the world of building and design, the relevance of welding assessment can not be overstated, as it plays an essential duty in making sure structural stability and prolonging the lifespan of jobs.Making certain the structural stability and safety of bonded building and constructions mandates rigorous welding assessment procedures.Building upon the importance of welding assessment in protecting structural honesty, understanding the crucial assessment techniques becomes imperative for efficient implementation. Efficient welding evaluation incorporates a range of approaches made to examine weld high quality, making sure compliance with strict engineering requirements - Welding Inspection Madison.Reliable welding assessment plays an essential duty in boosting structural integrity and long life by recognizing issues early in the building and construction process

Report this page